Novel Six-Bar Linkage Finger Clamping Device for Large Clamping Variance

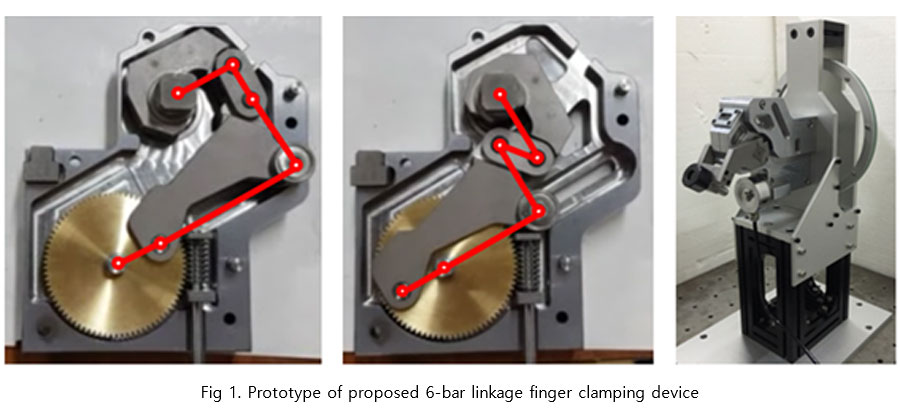

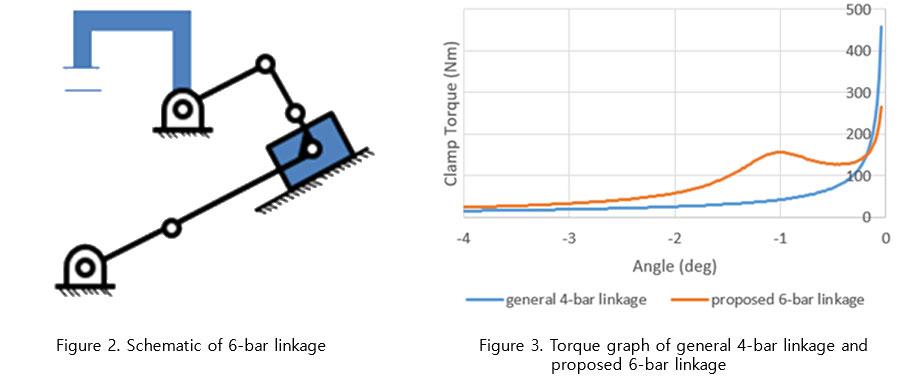

Finger clamping devices mounted on the end of robot manipulators are utilized for positioning and holding any objects securely (mostly a thin panel). These clamps have been widely used for chassis assembly process to be specifically intended to hold and assemble chassis components. However, these clamping devices have two main limitations. First of all, since most of clamping devices use pneumatic cylinders as power sources, there are complicated wiring issues in order to supply air pressure. The second limitation is the small clamping range. Most finger clamping devices use 4-bar linkage structure; however, they have small clamping range due to their kinematic nature as shown in Fig.1

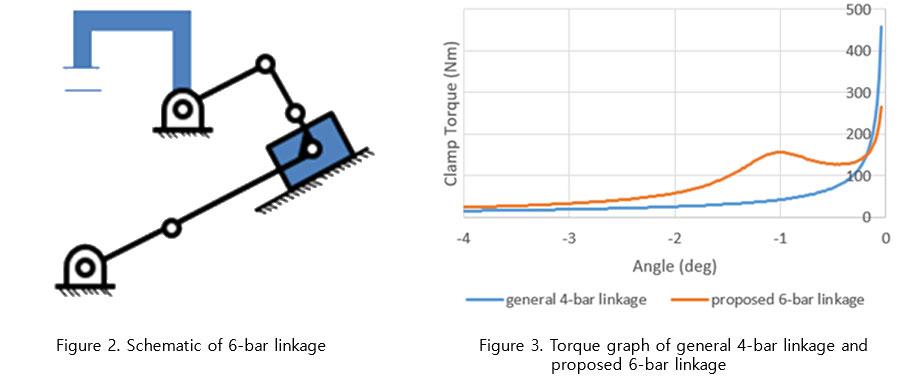

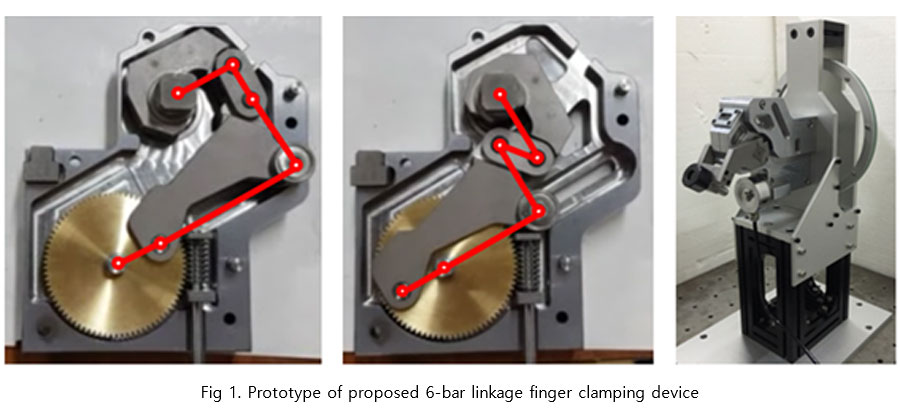

In order to overcome those of limitations, our team come up with novel electric finger clamping devices using 6-bar linkage(Fig.1). Since electric clamps use electric motors as the power source, they avoid complicated pneumatic line which is considered to be complicated wiring issue. Not only that, electric clamps also solve the issue for small clamping range. These electric clamps are composed of 6-bar linkage(Fig.2) that take advantage of their linkage structure effectively. Instead of loosing the torque as the angle decreases (Fig.3 general 4-bar linkage), torque from 6-bar linkage increases at some range of angle (Fig.3 proposed 6-bar linkage). This increase in torque occurs because the singular state is passed twice. Therefore, these clamps have bigger clamping range than existed pneumatic clamps do.

In order to overcome those of limitations, our team come up with novel electric finger clamping devices using 6-bar linkage(Fig.1). Since electric clamps use electric motors as the power source, they avoid complicated pneumatic line which is considered to be complicated wiring issue. Not only that, electric clamps also solve the issue for small clamping range. These electric clamps are composed of 6-bar linkage(Fig.2) that take advantage of their linkage structure effectively. Instead of loosing the torque as the angle decreases (Fig.3 general 4-bar linkage), torque from 6-bar linkage increases at some range of angle (Fig.3 proposed 6-bar linkage). This increase in torque occurs because the singular state is passed twice. Therefore, these clamps have bigger clamping range than existed pneumatic clamps do.